Table Of Contents

Safety Measures During Installation

When it comes to the Hot Water System Installation, ensuring safety measures are in place is paramount. Professionals in the field are well-versed in adhering to strict safety protocols before, during, and after the installation process. Prior to the commencement of the installation, it is crucial for the technician to conduct a thorough inspection of the area to identify any potential hazards or obstacles that may impede the installation process. By meticulously assessing the surroundings, the technician can mitigate risks and ensure a smooth installation process.

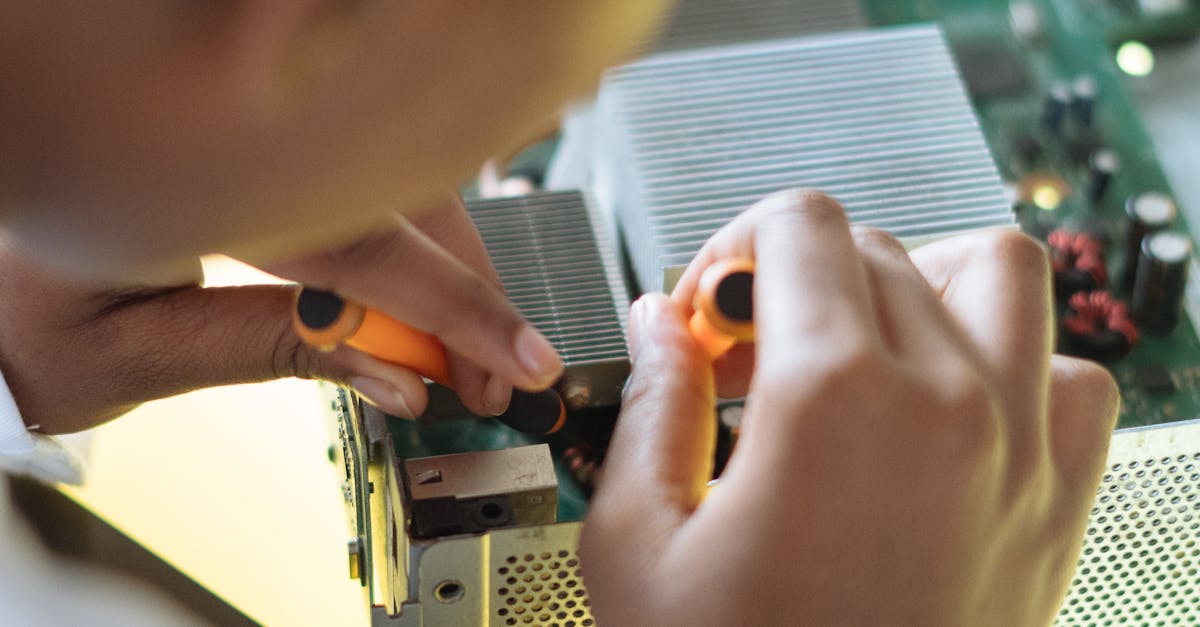

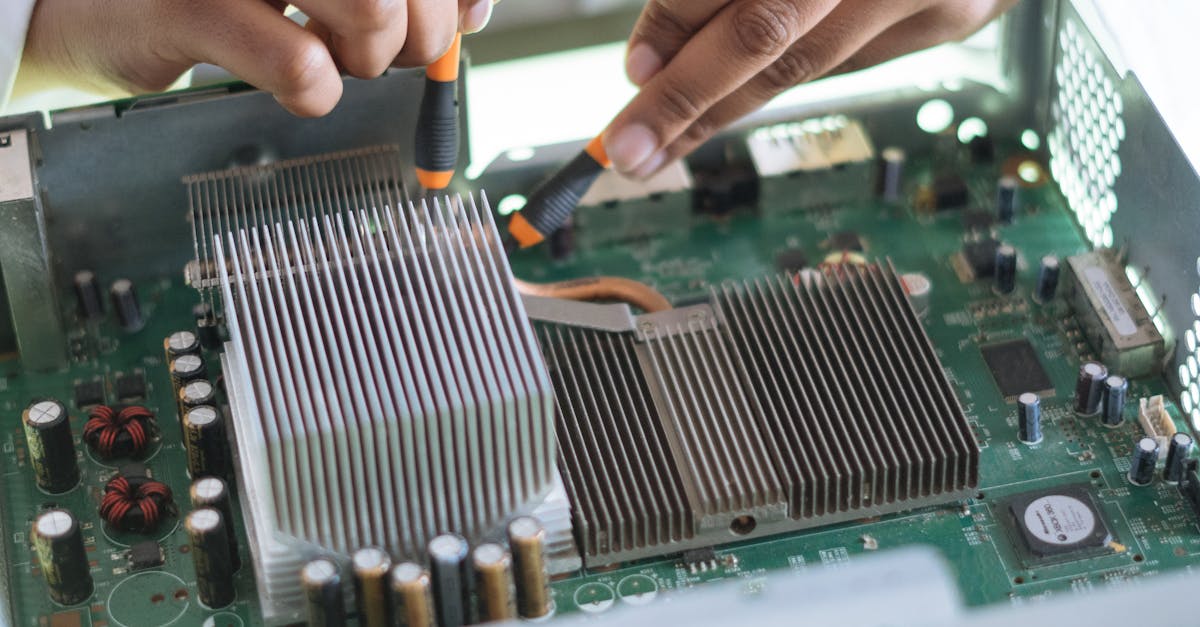

Throughout the installation of a hot water tank, professionals prioritize the safety of both themselves and the occupants of the property. This involves wearing appropriate personal protective equipment, following manufacturer guidelines, and utilizing specialized tools for the task at hand. By maintaining a keen focus on safety measures at all times during the Hot Water System Installation, professionals can execute the job efficiently while upholding the highest standards of safety and quality.

Checking for Gas Leaks

When conducting a hot water system installation, one crucial step that must not be overlooked is checking for gas leaks. Safety is of utmost importance during this process, and gas leaks can pose serious risks if left undetected. To ensure the safety of the installation and the occupants of the premises, it is imperative to diligently inspect all connections and fittings for any signs of leaks.

Gas leaks can be detected by using a soapy water solution to test the connections. Apply the solution to the connections and observe for any bubbles forming, as this indicates a leak. It is essential to address any leaks promptly to prevent potentially dangerous situations. Additionally, utilizing a gas leak detector can provide an added layer of security during the installation process. Heating professionals should always prioritize safety measures when conducting a hot water system installation, and checking for gas leaks is a fundamental aspect of ensuring a safe and successful installation process.

PostInstallation Checks

After completing the installation of a hot water tank, several post-installation checks need to be conducted to ensure the system functions correctly. Firstly, ensure all connections are secure and leak-free. This step is crucial to prevent water damage and ensure the longevity of the hot water system. Next, check the temperature settings on the tank to ensure they align with the desired hot water output. Adjustments may be necessary to suit the preferences of the homeowner.

Following this, it is important to test the pressure relief valve to guarantee it is functioning correctly. The pressure relief valve is a crucial safety component that prevents the tank from building up excess pressure. Additionally, check the overall performance of the hot water system by running several faucets simultaneously to assess the consistency of hot water flow. Conducting these post-installation checks is essential to ensure the successful operation of the hot water system installation.

Testing Hot Water Flow

After completing the hot water tank installation process, one crucial step is to test the hot water flow. This test ensures that the hot water system functions efficiently and delivers the expected performance. To check the hot water flow, turn on the hot water tap and observe the water temperature and pressure. It's essential that there is a consistent flow of hot water without any fluctuations in temperature or pressure.

The hot water flow test allows for the identification of any potential issues within the hot water system. If there are any irregularities in the hot water flow, it may indicate a problem with the installation or the hot water tank itself. By conducting this test as part of the Hot Water System Installation process, professionals can ensure that the system operates effectively and provides hot water as required by the end user.

Common Issues That May Delay Installation

During a Hot Water System Installation, professionals may encounter various issues that can potentially lead to delays in completing the task. One common problem that may arise is discovering unforeseen plumbing complications. This can include existing pipes that are corroded, leaking, or not up to code, requiring additional time and effort to rectify before installing the hot water tank securely.

Another factor that could hinder the installation process is the unavailability of essential tools or parts. If the professional does not have all the necessary equipment at hand, they may need to postpone the installation until the required items are obtained. This can prolong the overall timeline of the Hot Water System Installation and inconvenience both the technician and the homeowner.

Unforeseen Plumbing Problems

Unforeseen plumbing problems can significantly impact the timeline of a hot water tank installation. Issues such as corroded pipes, unexpected leaks, or outdated plumbing fixtures can pose challenges during the installation process. These unforeseen problems may require additional time and resources to address, leading to delays in completing the Hot Water System Installation.

Moreover, inadequate water pressure, faulty valves, or incompatible fittings are other common plumbing issues that can arise during the installation of a hot water tank. Addressing these problems promptly is crucial to ensure the proper functioning of the hot water system. Professional installers must be equipped to troubleshoot and resolve these unexpected plumbing challenges efficiently to minimize delays and ensure a successful Hot Water System Installation.

FAQS

How long does it typically take for a professional to install a hot water tank?

The time it takes for a professional to install a hot water tank can vary depending on factors such as the type of hot water tank, the complexity of the installation, and any unforeseen issues that may arise. On average, a professional installation can take anywhere from 2 to 4 hours.

What safety measures should be taken during the installation of a hot water tank?

Safety is paramount during the installation of a hot water tank. Professionals should ensure that all electrical and gas connections are secure, that the tank is properly vented, and that all safety valves are in place and functioning correctly. It is also important to follow manufacturer instructions and local building codes.

How can I check for gas leaks after the installation of a hot water tank?

To check for gas leaks after the installation of a hot water tank, you can use a gas leak detector spray or a mixture of dish soap and water applied to the gas connections. If you suspect a gas leak, it is important to turn off the gas supply immediately and contact a professional for assistance.

What are some post-installation checks that should be done after installing a hot water tank?

After installing a hot water tank, it is important to check for leaks in the connections, ensure that the tank is heating water properly, and test the hot water flow from faucets. It is also recommended to monitor the tank for any unusual noises or malfunctions.

What are some common issues that may delay the installation of a hot water tank?

Common issues that may delay the installation of a hot water tank include unforeseen plumbing problems such as corroded pipes, inadequate ventilation, or incorrect sizing of the tank. It is important for professionals to address these issues promptly to ensure a successful installation process.

What should be done in case of unforeseen plumbing problems during the installation of a hot water tank?

In case of unforeseen plumbing problems during the installation of a hot water tank, it is important to consult with a professional plumber to assess the situation and determine the best course of action. This may involve making necessary repairs or adjustments to ensure the proper functioning of the hot water tank.